Changing Direction Mid-Bore

Volume 8, Issue #4 – April 2022

The “directional” in horizontal directional drilling (HDD) means the driller can steer the bit in 3-dimensional space as it is pushed forward – up, down, left or right. A related question we hear quite frequently is, “What about changing direction mid-bore?”

This question usually comes up in the field when something has gone wrong. But occasionally it comes up in the pre-planning phase too.

And in the great tradition of wishy-washy driller’s answers we will confidently respond, “It depends.”

Changing Direction in a Directional Bore

There are several reasons why we might want or need to kick out of an HDD bore path.

Often, it’s because we’ve hit a retaining wall or some other subsurface infrastructure that wasn’t included in the site plans or as-builts.

The rest of the time we’ve probably hit some hard formation or boulder that pushed the bit beyond the acceptable deviation tolerance and can’t get back on target for one reason or another.

If the bit just deviated slightly and we can steer “back” onto the originally planned alignment, then obviously that’s preferable.

So, to be clear, what we’re talking about here is pulling back a ways, and then trying to “kick out” of an existing bore hole to go around an obstruction.

Fig 1: Should have taken that left turn at Albuquerque

If this obstruction occurs early in the planned bore length, then it’s usually an easy decision to just trip out and start over with a fresh entry alignment.

However, if we’re a couple hundred feet into the planned profile, the idea of starting over and re-drilling all that footage is pretty unappealing.

Geology Matters…A Lot

Whether or not the driller can redirect the bit mid-bore depends a lot on what type of formation we’re in. Very soft materials like sensitive fines and clays present steering challenges in general. They do not provide much reactive force to deflect the bit.

Harder material provides more reactive force, so getting that deflection is a little easier during normal steering operations. But it’s harder to kick out of an existing hole. The previously drilled hole in front of the bit provides a path of much less resistance than biting into harder, undisturbed formation.

Normally, borehole collapse represents headaches for an HDD operation. But it actually helps with changing direction mid-bore. Although sloughed material won’t have the same strength as the native formation, a little resistance is better than none.

So somewhat loose and soft (but not too soft) material offers the “ideal” conditions for kicking out of an existing hole. Even then, it’s easier said than done.

Kicking Out

All directional drill bits have an inherent asymmetry which allows for purposeful deviation during drilling. That’s why we call it “directional” drilling. But even in perfect geological conditions, that asymmetry might not facilitate enough “bite” to kick out of an existing hole.

So, usually the situation requires adding mechanical resistance to enhance the effect of that asymmetry.

One trick for generating that mechanical resistance is a kick plate. This device expands the amount of surface area the driller can push against to get the additional deviation necessary. But of course, normal bits don’t have kick plates. So, something needs to be fashioned in the field.

Recently the author was involved with a project where an unexpected obstruction (fill? rip rap?) had pushed the bit off the planned alignment. Other than the occasional random piece of fill, the formation was quite soft and prevented the driller from correcting the steer.

It seemed clear that we would not be able to get back on track with the current deviated trajectory, but starting over meant re-drilling several hundred feet. We didn’t have the means to rig up a kick plate, but we came up with something similar.

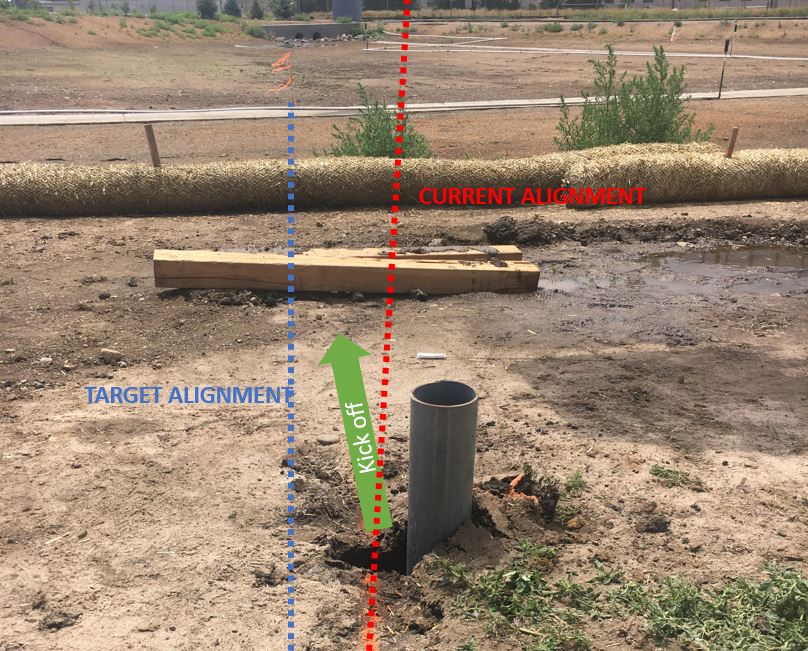

Fig 2: Inserting a steel pipe at the edge of a deviated bore path to deflect the bit in an otherwise “unsteerable” soft clay.

So, the driller tripped the bit back a couple rods (~20 ft or so) and the crew used an onsite hydrovac to push in a piece of scrap steel tubing just on the edge of the misaligned bore path.

Then the driller advanced the bit at “9 o’clock” (oriented for a left-hand turn). The bit glanced off the “kick-off tube”, providing enough angle to get a bite into fresh, un-drilled formation. This established a new bore path more in alignment with the original plan.

Know When to “Cut Bait”

Just because something is possible, doesn’t necessarily mean it’s the best course of action. Hopefully the discussion above illustrates just how difficult and complicated kicking out of an existing hole can be.

Sometimes changing direction of an HDD bore ends up working quite smoothly. You might kick out on the first try with a “normal” bit configuration. That’s great! You probably saved a bunch of time compared to tripping out and starting over.

On the other hand, you might spend hours and hours spinning your wheels. You might end up trying different points in the bore path, different down hole tooling configurations or even cockamamie ideas like the “kick-off tube” described above.

So obviously, we must weigh any potential efforts against the option of just “cutting bait” and starting a fresh borehole from scratch.

That decision often proves challenging in the field since many unknown variables dictate the level of effort involved. An experienced driller might have several tricks up his sleeve, but he’ll also realize that it needs to be worth the extra effort.

In other words: “It depends.”

Tags: borehole alignment HDD, directional drilling, horizontal wells, steering