Conductor Casing at an Angle

Elingson crews recently completed a horizontal dewatering well that featured a cemented conductor casing at the surface. While not every horizontal well requires a conductor casing, when this component is called for, it’s crucial to install it correctly.

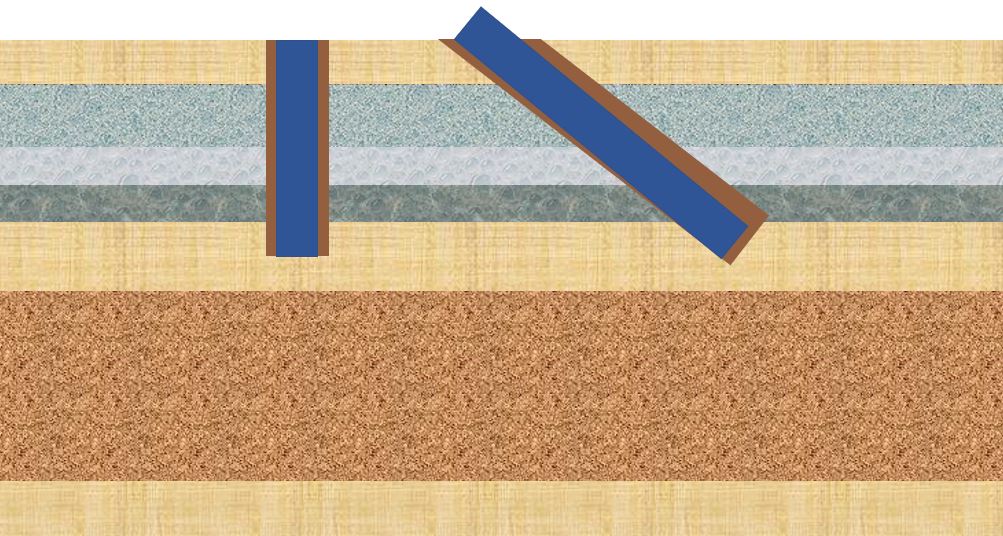

6-5/8″ drill pipe advancing inside of a 14″ diameter conductor casing

Conductor Casing Installation Process

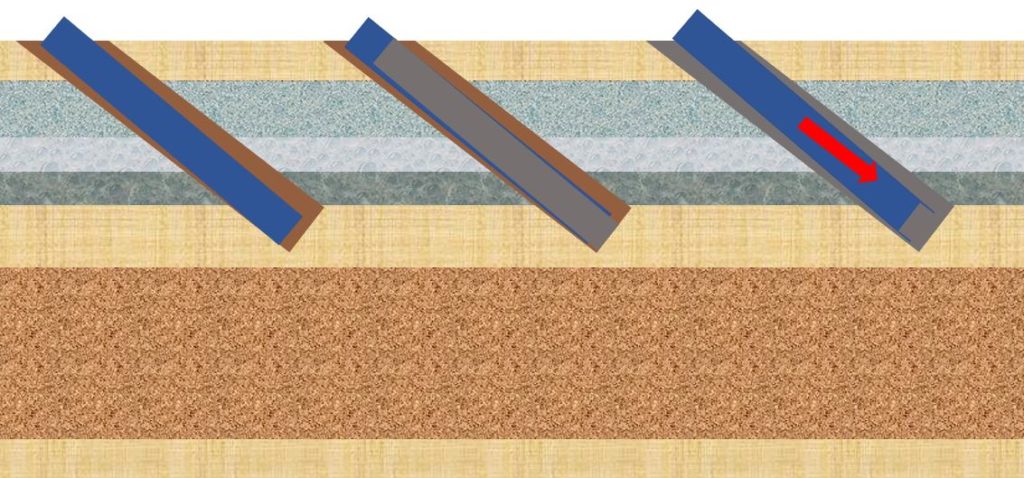

Since the orientation of HDD bores puts everything sideways, gravity works against you when trying to install a conductor casing at an angle.

In vertical applications the driller can easily hang the conductor casing (typically steel) in the borehole, perfectly centered. This orientation easily allows the placement of a tremie pipe for the full length of the casing.

However, in a shallow angle borehole, the casing will rest on the bottom of the bore. This causes the annular space to be irregular. As a result, the tremie slides around to the bottom of the casing and gets caught between the casing and the formation. This difficulty effectively limits tremie placement in angled bores to no further than 20 or so feet.

Therefore, when installing at a shallow angle, we prefer to utilize an “inside-out” grouting technique. This method helps to force grout into the entire annular space,

Crews fill the inside of the conductor casing with a volume of cement grout equal to the calculated annular space. The force of the rig (or a pump) pushes a plunger down the inside of the conductor, forcing the grout out the bottom and back up and into the annular space surrounding the casing.

Finally, a thin “plug” of grout remains at the bottom of the casing. After allowing adequate time for the cement to cure, the crew will drill through this plug continuing with the bore.

Coal Ash Dewatering

Ellingson has had the opportunity to complete several projects this year involving dewatering operations at coal combustion residuals (CCR) facilities. These CCR projects have included some of the longest horizontal wells we’ve ever installed.

Additionally, they’ve involved the installation of well screens both within and outside of the ash material in CCR basins. For one reason or another, many of these dewatering wells have required the installation of cemented conductor casings at the surface.

Horizontal gravity drain installed beneath a CCR basin

Ellingson crews have become quite proficient at this specialized technique. As we come across more unique dewatering applications, we expect to install a lot more cemented conductor casings in the future.

Tags: annular space, conductor casing, environmental HDD, grout seal, horizontal wells, surface casing