Thermal Remediation, Shallow Angle

Ellingson-DTD (DTD) directionally drilled six thermal remediation wells earlier this year. The project required source area remediation beneath a training facility at a military base in California. The wells provide In Situ Thermal Remediation (ISTR) in an otherwise inaccessible portion of a larger site. DTD joined a team of consultants and thermal remediation specialists, who oversaw the project and designed and built the actual ISTR system. The combined team worked for several months to develop a design for directionally drilled thermal remediation wells.

The primary cleanup efforts at the site involve vertical placement of several dozen thermal conductive heating assemblies. The thermal remediation wells consist of a “heater can”, or high-temperature heating element in a 3-inch steel tube. Above the “can” sits a one-inch perforated steel tube, to withdraw vapor liberated by the heating. These vertical heating assemblies are generally set at a depth of 20-30 feet below ground surface, with wellheads networked to a common power supply and vacuum.

Thermal Remediation Underneath a Building

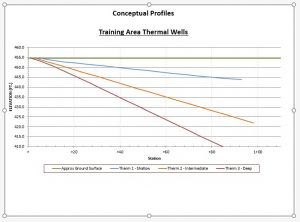

Where contamination extended beneath a training facility building, design efforts concentrated on how to tilt the vertical “can” configuration on its side. An angled configuration could cover a vertical swath of contaminated ground, while connecting to the wellheads from outside the building. The design team settled on stacked wells at various angles to simulate the effect of an array of vertical wells.

Where contamination extended beneath a training facility building, design efforts concentrated on how to tilt the vertical “can” configuration on its side. An angled configuration could cover a vertical swath of contaminated ground, while connecting to the wellheads from outside the building. The design team settled on stacked wells at various angles to simulate the effect of an array of vertical wells.

Initial designs explored the idea of installing the cans using unguided angle drilling; however, these notions were discarded with the realization that the angles needed were too shallow for most traditional rigs. Furthermore, they would struggle to install wells with the precision necessary for this application. Ellingson-DTD proposed using a small directional drill to install slightly arcuate wells, averaging the desired horizontal inclination (shown right).

Complicated Well Design Proved Challenging to Install

In late January 2020, the team mobilized a Vermeer 10×15 Navigator drill rig and support equipment to the site. The rig, which is CARB Tier 4 certified, is a small, rubber track mounted rig with 10,000lbs of push/pull force. This configuration provides plenty of power to drill and install single-ended wells up to ~200ft+. The team set up to drill two clusters of three wells each, fanning out at average inclinations of 9, 14 and 23 degrees from horizontal. In order to achieve these average inclinations with a drill rig with a limited range of entry angles, active steering started with the first rod – shallow wells steered upward, deep wells steered downward from the entry.

Small Directional Rig Installing Thermal Remediation Wells

Installing the well assemblies proved challenging because each well consisted of several different collocated components. The extraction screen had to be installed at a specific depth above the heater “can”. Additionally the assembly left little annular space for the tremie pipes needed to install grout and filter pack. One of the wells even included a 1/2-inch thermocouple!

The lower “cans” were grouted with a high temperature cement/silica cement to enhance thermal transfer to the surrounding soil, while the upper screened interval consisted of a pre-packed, stainless steel, one-inch well screen. The original design called for additional sand pack tremied around the pre-pack; however, crews achieved this objective with limited success. Mostly this just provided a sand bridge at the top of the screen interval, preventing migration of surface seal grout.

Project Completed On Time and Under Budget

Once the crew fine-tuned their process and hit their stride, productivity approached one well per day. The final tally included six (6) heater assemblies with varying measured lengths between 80-90ft. Total footage drilled came in at 520 linear feet.

Throughout the project, Ellingson-DTD coordinated closely with the project team to respond to minor issues with well alignment, utility avoidance, and waste management. The crew completed the project on time and slightly under budget. The consultant and remediation contractor will start up the system later in the year, after completing the electrical and vapor extraction hookups.

Tags: angled wells, difficult access, directional drilling, DOD sites, thermal conductive heating, thermal remediation