The Longest Well

Volume 8, Issue # 9 – September 2022

When discussing horizontal wells with someone unfamiliar with the technology, we frequently encounter questions related to the tooling limits. Typical examples include, “How deep can you go?” or “What’s the biggest diameter you can install?”

We find it interesting that questions about depth and diameter come first to mind. They are logical queries for someone encountering a novel way to drill a hole, as those limitations are the common defining boundaries for various vertical drilling methods.

However, HDD is just direct mud rotary (turned sideways). And mud rotary is hardly a new drilling method.

An old mentor used to say that “refusal” with mud rotary is simply an economic limitation. In other words, depth is only limited by the rig’s pull back, and diameter is only limited by the mud pump’s capacity. So, these questions are really just reflecting how much has been invested in the equipment’s capabilities.

In the HDD world the real question is “how long of a bore can you drill?” This question is directly related to the maximum push/pull capacity of the rigs in a contractor’s fleet.

We’ll ignore the question of diameter for this newsletter, and just say that once you get to around 30”+ in borehole diameter, you are encroaching on the scale where micro-tunneling becomes much more practical than HDD

Fig 1: Stainless steel well casing strung out on the exit side of a 2,000ft+ horizontal well.

So…How Long of a Well CAN You Drill?

We’ve said it before, and we’ll say it again…“it depends”.

As discussed above, the total length of bore a rig can achieve is a function of the push/pull capacity. Drill rigs are available in a variety of sizes and capacities, from those that can be driven through a residential garden gate to rigs that require multiple tractor-trailer loads to mobilize.

Those limited access rigs might max out at 10,000lbs of push/pull force, which equates to a couple hundred feet max length in good geological conditions. Meanwhile the largest rig packages have pullback capabilities of over a million pounds (the record for an HDD bore is a 17,060ft shot).

Ellingson operates up to 800,000lb push/pull machines, and our company record is a 7,000ft river crossing. Chances are we have equipment capable of drilling a well as long as you could possibly need, but there are several other important questions to resolve first.

How Much Space is Available?

When installing horizontal wells, particularly in environmental remediation applications, the area available to setup the rig is a crucial constraint.

For wells up to about 500 feet, the equipment setup will include a drill rig ranging between 15-30ft long, while wells in the 500-1,000 foot range will likely need a rig that is 30-40 feet long. This rig will also require a larger mud system, so the total construction footprint starts expanding.

Wells in the 1,000+ foot range require progressively larger rigs that can handle 31.5-foot drill rods. These rig setups will include the rig, an adjacent rod trailer or two, an excavator for rod handling, a large mud system, space for several rolloff boxes, a driller’s control trailer and a tooling trailer.

That can take up a lot of space and also requires a drilling pad capable of truck access to position all that equipment. If your site can’t accommodate that, perhaps the solution is to drill additional, shorter wells that can be installed with a smaller rig, and probably at lesser cost.

Fig2: Limited space for rig setup may also limit the total length of horizontal well that is feasible.

How Long of a Well Do You Really Need?

Well lengths for most environmental sites are constrained primarily by the size of the contaminated zone and/or the property boundaries. Cutting off a plume 300 feet wide would, in most cases, require a well with a 300 foot well screen. Add the setback distance needed for the depth (we’ve covered this before – a 5:1 ratio) — to one or both ends and you have your total well length.

In some cases, the well length may be constrained by the selected treatment. You can only pump so much fluid into or out of a well of a given diameter and length. A groundwater extraction well pumping rate is constrained in part by the pump and discharge pipe diameters needed to move the water. Eventually you reach a point of diminishing returns, which is typically around a 12-inch diameter well with a screen a few hundred feet in length for groundwater extraction.

For soil vapor extraction, you run into treatment technology limitations long before you reach the limits of potential well lengths. Sure, it’s possible to install a 2,400ft long SVE well, but frictional losses, blower size and energy requirements would be enormous. The better design would include several wells to cover that distance.

On the other side of the spectrum, take installing a 2,400ft gravity drain to dewater a coal ash pond? Why not? The longer the screen, the more pore water it will capture. Our current record for total length of a horizontal well is just under 4,000ft, and it was just this sort of application.

Other Factors to Consider

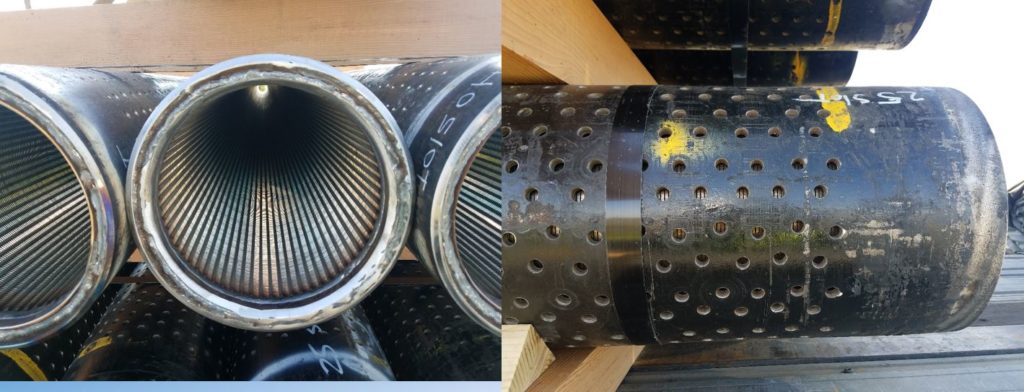

Practical limitations of well design include the tensile and compressive strengths of the well materials. Slotting pipe to make it into well screen can reduce the tensile strength dramatically, so well material selection, diameter, wall thickness and slotting pattern are key factors in designing longer wells.

In a short well, it may not matter if the slots run perpendicular or parallel to the long axis of the pipe. But those two configurations differ greatly in the remaining tensile strength after slotting, enough to make the difference between a successful well installation or broken pipe. In wells beyond a few hundred feet, steel materials are generally going to be the best bet for success.

Fig3: When designing long horizontal wells, material selection and screen design must strike a balance between cost, slotting pattern/open area and strength.

The well configuration (i.e. whether completed as double- or single-ended) is a huge factor in determining the max length well that can be installed in a given situation. It is more challenging to push pipe into a borehole than it is to pull it back through. So, longer well designs will benefit from the availability of an exit point.

If access for an exit side is an issue, Ellingson can provide our patented Knock Off (single-ended) technology for single-ended completions in excess of 1,500ft; however, that tooling package requires a big rig setup (see above RE: site setup limitations).

Don’t Forget About Geology

And, of course, all these factors relate in one way or another to the geology. All else being equal, difficult formations may require a little more horsepower in the rig package to achieve the same length bore.

Whether that bigger rig fits in the available setup space, or whether those well materials will stand up to the increased energy during installation must be taken into consideration.

Like most questions, when someone asks how long of a well we can drill, there is no simple answer. If you have an idea for a horizontal well but aren’t sure if the dimensions you’d need are feasible, give us a call.

It’s usually best to look at each case individually.

Tags: HDD, horizontal well, knock off, long screen