Is A Pilot Study Really A Study Or Is It Just Another Exercise?

Okay, we have a confession to make; most drilling contractors hate “pilot studies”. A pilot study project starts like this – A consultant will reach out to a driller like Ellingson-DTD and ask them for a one-well estimate. They inform the driller this single well will serve as a pilot study to see if horizontal wells will provide effective remediation at a site. Often, we hear a statement like, “if it works there will be lots of wells during the full-scale phase,” implying that keeping unit pricing aggressive will pay dividends later. Many times this never occurs. Why?

1) The pilot study doesn’t start.

2) The pilot study results are inconclusive.

3) The consultant loses the contract with the owner and a new consultant wants to start from scratch.

4) The pilot study works, and the consultant goes out and re-bids the unit pricing anyway. And that’s why pilot studies drive us crazy.

#4 is frustrating, especially when the horizontal drilling contractor provided valuable insight that helped develop the work plan of a successful study. But we’d still take it over #1 any day. And those issues are sometimes related.

Pilot Studies Are “Too Expensive”

Many pilot studies die on the vine because they are deemed to be “too expensive”. Now we realize that horizontal wells are not going to be the most cost-effective approach for every single site, but please be careful extrapolating pilot study prices out to “full scale”. Don’t rely on vague promises of a big project in the future to drive down the unit rates for the small-scale trial now.

Most everyone intuitively understands that bigger projects don’t scale up linearly because we only need to account for “mobe/demobe” once. But that is only part of the picture; there are more economies to be found at scale.

There are plenty of non-mobilization related costs that are still incurred regardless of the scale of the project. As one-time costs, these can be spread out further the more footage is involved in the scope.

The Value of Familiarity

Don’t underestimate the value of familiarity either. Drilling is a notoriously difficult activity to accurately estimate because penetration rates vary widely with the geology encountered. While we can glean a lot of information from nearby boring logs and geotechnical reports, nothing compares to direct site experience.

Finally acceptable project margins come down with 1) scale and 2) confidence. So, if the contractor has more certainty about how the project will unfold (because they’ve worked there once already) and it’s a relatively “big” job, the footage price can be bid more aggressively.

But you’re not going to reap this benefit until AFTER the pilot study is completed. So this is all to say that you should be leery extrapolating the pilot study costs linearly to evaluate full-scale costs.

Pilot Studies Do Work

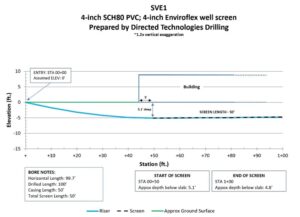

Of course, pilot studies really do work. For example, Ellingson-DTD mobilized to a site in an Eastern US state for a one-well, sub-slab, “pilot study” soil vapor extraction well. The short 80’ well was completed 5’ below an operating manufacturing plant in a blind (single entry) borehole. It only took one day to rig up, drill and install the well. As with many sub-slab wells, this installation was completed slightly shorter than planned due to a utility at an unknown depth along the bore path. The objective of the pilot study was to determine the following:

- Could horizontal wells be installed at the site without disrupting the ongoing facility operations?

- Would a “pre-packed” screen work (EnviroFlex™) for an SVE application?

- What is the radius of influence from the SVE well?

The Findings

Based on the one-day field effort we determined that a horizontal well could successfully be installed 5’ sub slab at the site with no impact to operations. Two other determinations were made. The underground utility maps were old and of poor quality and EnviroFlex™ prepacked well screen could be completed in a blind borehole. What we didn’t know yet was the ROI of the SVE well and would the remediation be effective.

Fast forward one year – we were again contacted by the consultant and low and behold – the ROI of the horizontal well was such that the full-scale project would be implemented.

The Scope of Work

The full-scale work scope was an additional five blind wells, similar to the pilot well. Each well was to be completed in a blind borehole, 5’ below the slab with screen lengths ranging from 50’ to 125’. This field effort lasted ten days and the biggest challenge was identifying the depth of all the utilities which conflicted with the well paths. In fact, one of the wells passed so close to a utility the decision was made to expose the buried line and watch the directional drill bit pass the potential obstruction.

Do We Really Hate Pilot Studies?

Maybe it’s unfair to say that drilling contractors hate “pilot studies”. Really that statement was mostly tongue in cheek. We realize that this type of project is needed in many cases to prove a remedy will work at a specific location given the site-specific conditions.

Please let us know how we can help evaluate all the potential pilot study projects you have.

Tags: pilot studies