Extracting Water from Horizontal Wells

Volume 8, Issue #6 – June 2022

There isn’t a more pure or fundamental application for a well than extraction. That is, after all, why we started drilling them in the first place.

While most wells are drilled in a vertical orientation, the alternate geometry afforded by a horizontally installed well screen, drove the first directional drillers to “turn sideways” and more efficiently extract from the petroleum reservoirs they were targeting.

While the high economic value of petroleum products has driven (and continues to drive) most of the technological advances throughout the history of horizontal/directional well drilling, this month’s newsletter will focus on the related application of groundwater extraction.

Horizontal Groundwater Supply Wells are Great for Thin Aquifers

Groundwater often occurs in relatively recent sedimentary geology, like river channels or lake beds. In those cases, the geological units are usually flat and parallel to the ground surface. When the permeable layer (the aquifer) provides a relatively thin saturated thickness, a horizontally oriented well screen can get more water per well head compared to vertical wells.

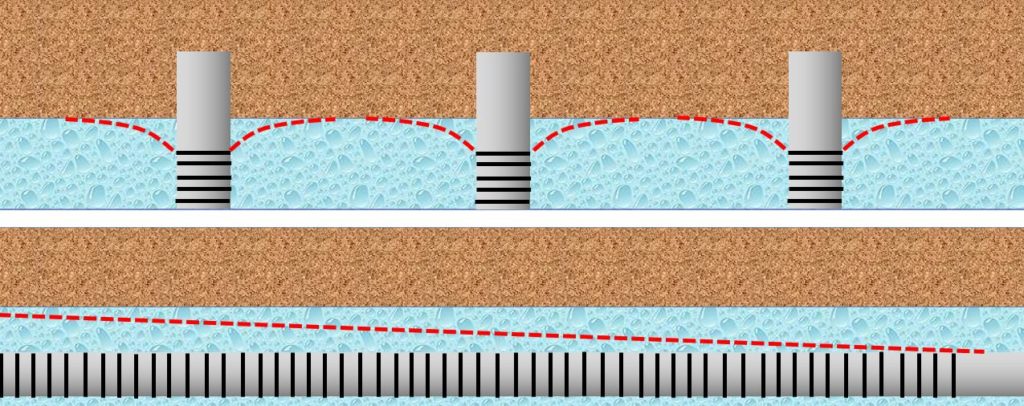

This increased productivity is simply a function of getting more screened area within the productive zone. Turning the well’s orientation on its side spreads out the drawdown along the length of the horizontal well screen. While a vertical well’s screen length is limited to the thickness of the aquifer less the drawdown losses.

Fig 1: A horizontal well screen can extend laterally throughout the aquifer, exposing orders of magnitude more screened surface area to the productive formation.

Surface Water and Groundwater Interactions Add Benefit of Accessibility

Another unique aspect of horizontal wells is the fact that the well head is not oriented immediately over the placement of the well screen. This is particularly useful when the project is leveraging the connection between surface water bodies and the groundwater.

One example includes riverbed filtration applications where a supply well taps into the alluvial aquifer beneath a surface water body. A horizontal well screened beneath a river or creek can extract surface water without the costly/complicated permits required of a surface intake. Horizontal wells can also provide the benefit of placing the wellheads in a more convenient or secure location, away from potential damage from floods, wave action, or even ice rafting.

Plus pulling the water through fluvial sediments provides a first-cut filtration effect, which can reduce overall treatment cost and complexity.

Fig 2: Pump testing a horizontal water supply well (~700gpm constant rate test)

The geometrical advantage of long-screened horizontal wells can also benefit aquifer recharge applications. This might include horizontal infiltration wells beneath recharge basins to optimize recovery. Or it might involve long horizontal injection wells that deliver recharge water below a shallow impermeable perching layer.

Horizontal Wells: An Excellent “Fit” for Unique Dewatering Challenges

Coal ash ponds and mine tailings impoundments represent some of the most difficult dewatering challenges in the civil/environmental space. The sheer scale of these ponds can be overwhelming, and the impounded material can exhibit a number of incredibly complex geotechnical, chemical and hydrogeological characteristics.

Additionally, the basins are often either capped with an engineered material or their thixotropic nature is simply too unstable to support equipment on the surface. Either way, installing vertical well points is often infeasible, impractical, or unsafe in these conditions.

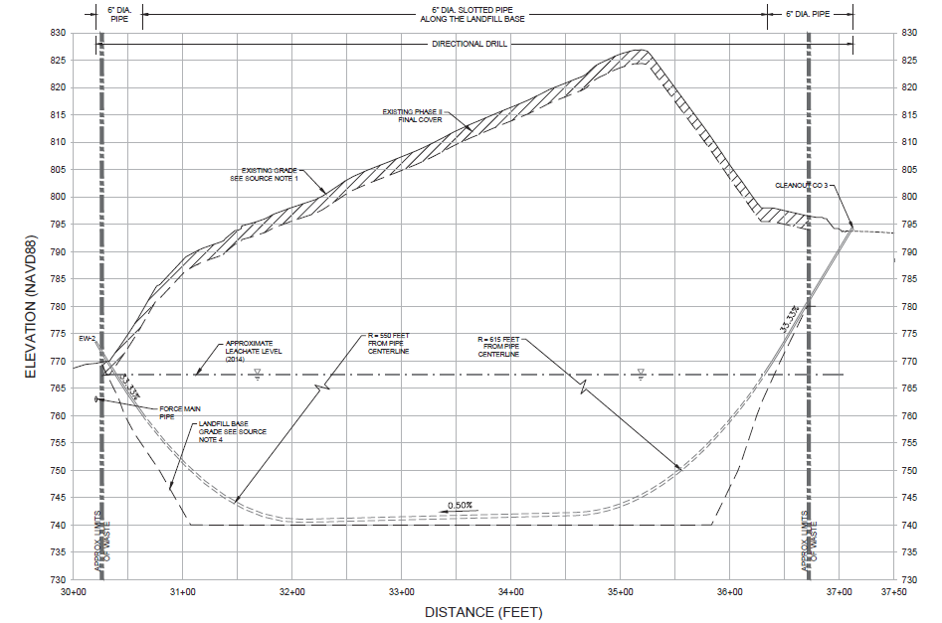

Horizontal directional drilling (HDD) facilitates the installation of very long dewatering well screens that can match the geometry of these impoundment facilities even when they’re thousands of feet wide.

Fig 3: Cross sectional profile of a horizontal dewatering well in a coal ash basin (screen length ~550ft)

Certain configurations can provide gravity fed draining, while others might incorporate active pumping designs. Additionally, the well heads can be oriented such that no equipment needs to drive out on unstable materials, nor do hundreds of wellpoints need to penetrate an engineered cap. Further, horizontal wells can continue to drain impoundments even as ash or tailings are removed above the well. In most cases, vertical well points are destroyed as lifts of materials are removed on pond reclamation projects.

Finally, horizontal dewatering wells will have very long screen sections which spread the total flow rate of a dewatering application across a very long lateral distance. This reduces the entrance velocity to nominally low levels. As a result, long-screened horizontal dewatering wells do not suffer much from siltation or solids buildup in the well screens, which keeps rehabilitation and maintenance costs down.

Groundwater Extraction Treatment Systems – An Oldie but a Goodie

Last but certainly not least, we cannot forget groundwater extraction for the remediation of contaminated plumes. Horizontal wells enjoy a rich history with this particular application. In fact, groundwater pump and treat systems were the original use case for the development of HDD installed wells.

Once again, access issues often represent a big driver for turning traditional vertical extraction wells sideways. Groundwater contamination tends to occur at industrial sites and other highly developed areas, which means that the areas most in need of screen intervals might often be located beneath surface infrastructure. Further, plumes that leave the immediate site often pass underneath neighboring properties where the cleanup owner may not have permission for entry or construction.

Whether the objective is up-gradient mass removal or down-gradient hydraulic control, horizontal wells can be deployed in all sorts of environments where surface infrastructure precludes or at least complicates the installation of traditional vertical well orientations.

Common applications include (but certainly aren’t limited to) railyards, airfields, manufacturing facilities, busy highways, pipeline easements and many other “limited access” situations.

Of course, in environmental pump and treat applications, geometry plays a role too. “Capture” is the name of the game and getting adequate coverage across the full lateral extent of a plume can often require a lot of vertical wells. In those situations, system design engineers must consider that each vertical well head will require its own pump, power connection, pump control and conveyance piping back to the treatment system.

A single, long-screened horizontal well can replace multiple vertical wells and the surface appurtenances that go along with them. On top of that, the design can usually involve placement of that single horizontal well head near the treatment system, minimizing conveyance costs.

Horizontal Water Extraction Wells Offer a Wide Range of Site Solutions

Whether the application is clean water supply, extraction for environmental remediation purposes or unique dewatering applications, horizontal wells can play a role.

Sometimes it’s because of access issues at the surface and other times it’s the geometry of the formation holding the water; either way, the unique design of horizontal wells and directional control of HDD methods open a world of possibilities.

Tags: groundwater extraction, horizontal wells, water supply