History of Horizontal Wells

Volume 8, Issue # 10 – October 2022

Directional drilling began with surveying of oil and gas wells in the 1920s. Around that time drillers realized many of their vertical wells had deviations, and some of the deviations were significant. After devising ways to survey these well deviations, it was recognized that the offset of the vertical wells could be used to some advantage.

Drillers soon began setting and orienting metal wedges at the bottom of their boreholes, and then continuing drilling. The wedge would deflect the drillhead and directional drilling was born. For what it’s worth, those downhole sacrificial wedges were an early version of the whipstock.

Horizontal Wells from the Beach

Among the very first directionally drilled wells were those used to reach near shore oil deposits in Huntingdon Beach California in 1930

Their use naturally expanded to adjacent Signal Hill, where by 1932 wells were regularly being drilled with a directional component. Directional drilling to hit laterally extensive oil deposits was one thing, but hitting a small target from afar, is quite another. And that is what was needed for directional drilling to come into its own.

Fig 1: Huntington Beach, 1926

In south Texas, the Conroe Crater formed in 1933 as a vertical oil well blew out and erupted into flames, eventually swallowing the rig and two of its neighbors. After almost one year of flames and uncontrolled eruption of oil, H John Eastman was brought in from the California oil fields to directionally drill and kill the Conroe Crater well.

Eastman successfully navigated his bore, intercepting the oil deposit near the blown out well, and by injection of water, effectively stopped oil flow to the uncontrolled vertical well. The ability to drill precisely to a deep and remote location launched directional drilling into prominence. As we fast forward 90 years, 81% of all oil and gas wells are directionally drilled.

Early Horizontal Water Wells

Around the same time, water supply applications also began to explore the benefits of “going sideways”. Leo Ranney (who came from the oil patch) began using radial collector wells for groundwater extraction in the mid 1930s. The first Raney water collector well in the United States was installed in 1936.

A collector well consists of one large diameter caisson dug near the bank of a surface water body (river, creek, lake, etc.). Horizontal well screens are then driven radially from the bottom of the caisson like bicycle spokes beneath the surface water feature.

The long lateral screen lengths in the riparian aquifer fill the caisson where the water is pumped out using high-capacity vertical turbine pump(s).

Another horizontal water application developed soon after this in the early 1940s. The California Highway Commission (predecessor to CalTrans) pioneered the use of “hydraugers” for horizontal drain installation. The main objective of these dewatering wells targeted slope stability.

Like the radial arms in a collector well, these horizontal drains do not utilize directional drilling or steering. The lateral bores tend to extend straight out from their origin without any precision placement.

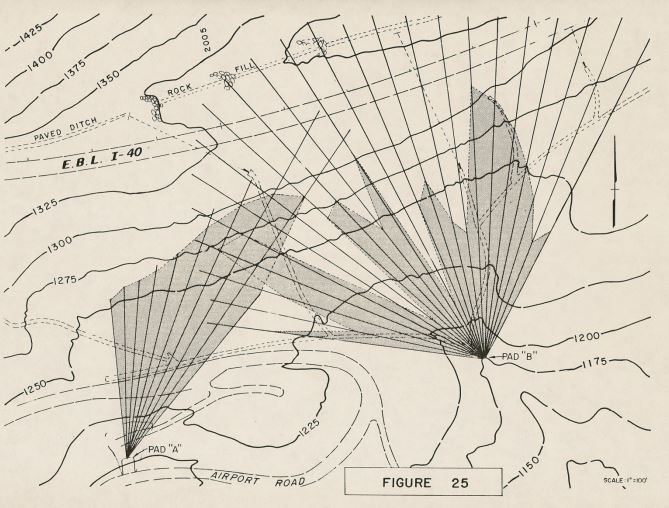

Fig 2: Fanned array of “hydrauger” horizontal drains to stabilize a slope.

River and Road Crossings for Utility Installation

While directional drilling for oil and gas has been around for nearly a century, its use for utilities is approximately half that.

The first directionally drilled utilities were short gas line road crossings and connections, again in California, in the late 1960s. But it was Martino Cherrington’s 1971 crossing of the Pajaro River near Watsonville, CA that really ushered in the new era of HDD. And by the early 1980s, horizontal directional drilling (HDD) as we now know it was being used across the US to install utilities, big and small, under rivers and roadways.

The next big advance was in navigation. With longer river crossings, the slow and expensive process of sending a camera down hole to snap pictures of a compass by the drill bit, and using it for navigating, still made economic sense.

But for short road crossings, where accuracy was still important, this cumbersome process was not viable. With the advent of computing technology, and perhaps more importantly, microcomputing, transmitters were developed that could be placed down hole, and tracked from the ground surface.

While these systems were initially not as accurate as the more expensive systems, they were fast, and accurate enough for use on short shallow bores. Soon drillers could not only know where a drill bit was, but also its orientation, and with that, HDD came into common use for underground utility installation.

Fig 3: A 1997 Vermeer 24a installing horizontal air sparge wells in Mississippi in the early 2000s

Environmental Remediation Applications

As HDD for trenchless utility installation became more common, savvy environmental engineers saw an opportunity to use the utility-type rigs for horizontal well installations.

The very first use of HDD for the installation of horizontal remediation wells was in 1987 in Ponca City, Oklahoma.

The wells were used for contaminated groundwater extraction at a Conoco refinery. The following year, Conoco installed two additional air sparge wells at the same facility, while 1,000 miles further east, the Department of Energy installed a deep horizontal sparge and paired it with shallow horizontal soil vapor extraction wells at the Savannah River National Labs in South Carolina.

These horizontal wells, and especially the outreach via DOE’s technology research and development program, ushered in the modern era of horizontal wells for environmental remediation.

An industry survey conducted in 1993, just five years after the first DOE found that at least 106 horizontal wells (non-oil/gas wells) had been installed.

This survey was repeated again in 1998, when it was estimated that over 1,000 horizontal wells had been installed in the environmental remediation industry. And by this point, horizontal wells were being used for almost any technology a vertical well could be used.

In the intervening years, multiple thousands of horizontal wells using HDD technology have been installed. Environmental remediation wells are by far the most common, however; the applications have expanded into the water supply and dewatering realm as well.

The history of “drilling crooked on purpose” is a rich tapestry of innovation, ingenuity, and creativity. And we’re proud to be a part of that industry.

Want to learn more about horizontal wells? Schedule a brownbag or webinar today!

Tags: directional drilling, environmental remediation, HDD, history, horizontal wells