Setbacks: They Aren’t What You Think

If your horizontal directional drilling (HDD) contractor calls to inform you that, “We’ve had a bit of a setback,” don’t immediately imagine that the drill rig tipped over, or that there’s a broken hydraulic line on a piece of equipment! More than likely, they are wanting to discuss the need for a little more space between the drill entry and the well screen.

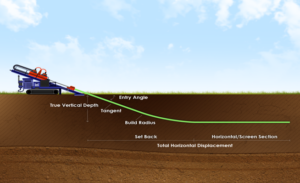

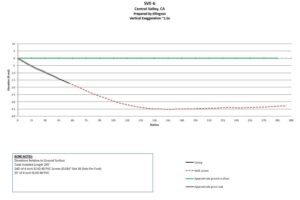

“Setback” in HDD parlance is the horizontal distance from the bore entry to the tangent point on the entry curve where the bore transitions to horizontal (zero degrees pitch/inclination). This usually coincides with the start of the well screen, but it doesn’t have to. The well casing connecting those two points is called riser pipe or riser section. Setback occurs at the opposite end of a double-ended well, too – where the exit riser ascends to the ground surface from the distal end of the screen.

The “Knock Off” method, sort of breaks the setback rule of thumb. The Knock Off drilling and installation technique allows us to build 4” diameter blind wells to great lengths (longest to date is 2,660’) and in difficult drilling conditions. However, this method utilizes a large diameter steerable steel casing for drilling, therefore using this approach requires a larger setback than typical.

Setbacks are Influenced by Several Factors

Setback is needed because we don’t drill vertically to the target depth and magically make a right-angle turn. All HDD involves curved boreholes. The amount of curvature (the bend radius) is influenced by several factors. The most important is the diameter and stiffness of either the drill rods or the well casing and screen that is to be installed. The larger and/or stiffer the pipe involved, the greater the bend radius we need to safely install the well without either permanently bending the drill rods, kinking the well casing, or damaging the well screen.

The other main factor in determining setback distance are the formation characteristics. Drilling in relatively compact, cohesive soil represents ideal conditions. The bit can be steered along the designed bore path at the proper bend radius without issue. But if the soil is loose, it may not support aggressive steering and the planned bore might need to have entry and exit curves extended to enable a gentler approach to steering.

How does all this apply when you want to design a well? The first thing to remember is that you don’t need to know all the nuances of setback and bend radius – it’s the HDD contractor’s job to work with you on the design and provide recommendations on feasibility. If you can provide the well materials composition, diameter and preferred location for the start and end of the screen, along with its depth, and some boring logs that characterize the soil, we can work with that data to provide you with our recommended setbacks.

Industry Rule of Thumb

But what if you’re not quite ready to contact an HDD expert? What if you’re just wanting to consider some different alternatives, and want to see if a horizontal well will fit your site? Here’s where some industry “rules of thumb” can be applied.

For wells up to about 6-inch diameter, you can safely apply a setback distance based on a 5H:1V ratio. For every foot of depth (V), figure you will need about five feet of setback (H). So if you want a screen at 30 feet, in “typical” soil with a medium sized drill rig, you’ll need about 150 feet to achieve that depth. You may be able to get by with less, but it’s really up to the contractor to make that call. Don’t forget to allow for about 30 to 70 feet (depending on well length and diameter) for the drill rig at the entry end and ample room for support and ancillary equipment.

For wells greater than 6-inches in diameter, long wells that might need to have their bores reamed larger, or stiff well material (like steel or stainless steel), you might need to increase to a 6.5H:1V or greater setback. For these wells, you might consider using another rule of thumb: take the largest diameter piece of steel that’s going in the bore – either the drill rods or the well casing — and multiply the diameter in inches by 100. That number is the minimum bend (build) radius in feet. A 12-inch stainless steel well screen will require a bend radius of around 1200 feet, which will likely exceed the 5H:1V ratio rule of thumb, probably by a lot.

Note one of our drilling techniques, specifically

What if you really need to have a screen start at a certain location – say, the edge of a plume – but there just isn’t enough space to fit a drill rig and the setback distance in and still hit your target depth? Always remember – rules (even rules of thumb) can be broken.

If you’re installing soil vapor extraction wells, we may be able to start the screen in the entry curve and still get good performance. Say you’re drilling to a target depth of 30 feet, requiring a setback of 150 feet (speaking generally here….). The bore will likely be at a depth of 28 feet at a distance of 10 feet before it gets to the target depth. With an SVE radius of influence of 10-15 feet or more, you may be able to start the screen up into the riser curve without any measurable difference in performance.

Similarly, extraction wells – depending on depth of submergence – might be treated in the same way. Perhaps you can run the screen up the riser for some distance (still below the water table), place a short piece of solid pipe where you want the pump to sit (so you aren’t sucking fines directly through the well screen) and achieve your capture area.

One remediation mode where we wouldn’t casually recommend starting the screen in the entry curve is on air sparge wells. The flow rate of air through the orifices along the sparge well is, in part, determined by the hydrostatic pressure acting on the well. If the leading slots in the screen are shallower than those farther down the screen, you could end up starving the distal end of the screen for air, while increasing flow through the slots closer to the wellhead. If you are considering such a configuration, make sure you design for it, with fewer or smaller slots in the elevated screen segment, or use other means of compensation.

Setbacks are a part of drilling – both the well design effort and a minor rig hydraulic leak. But there is no reason for either type of setback to stop your proposed project. A competent HDD contractor will help you design the first type and has the experience to deal with the second type!

Tags: double-ended wells, setbacks