4 Blind Horizontal Air Sparge Wells for Jet Fuel Remediation

DTD has recently completed the installation of four blind air sparge wells ranging from 360 to 600 feet in length. The horizontal wells were completed at a national airport, with three wells extending beneath the tarmac. Complicating the installation was the difficult ground: construction fill (debris including broken tarmac concrete and rebar) overlying resilient saprolite and weathered crystalline granite.

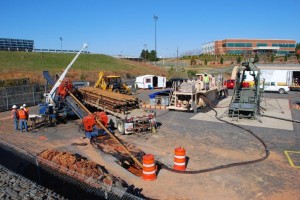

Drilling was completed with a mud-motor and tri-cone bit driven by DTD’s American Augers DD210. The drill rig and all support equipment (drill rig, the drill rod, mud recycling system, and support trailer) can all be seen in the site layout photo to the left. Existing site infrastructure and the multiple wells in a small area made for a challenging set up. All cuttings and waste were containerized in a lined rolloff with secondary containment incase of leakage or spills. A photo showing the rolloff, secondary containment and the mud recycling system can be seen below to the right. In addition to the rolloff, a closed top frac-tank was staged on site. The frac-tank took any liquid waste, including any decanted from the the top of the rolloff.

Drilling was completed with a mud-motor and tri-cone bit driven by DTD’s American Augers DD210. The drill rig and all support equipment (drill rig, the drill rod, mud recycling system, and support trailer) can all be seen in the site layout photo to the left. Existing site infrastructure and the multiple wells in a small area made for a challenging set up. All cuttings and waste were containerized in a lined rolloff with secondary containment incase of leakage or spills. A photo showing the rolloff, secondary containment and the mud recycling system can be seen below to the right. In addition to the rolloff, a closed top frac-tank was staged on site. The frac-tank took any liquid waste, including any decanted from the the top of the rolloff.

The bore design called for a large radius curve through the construction debris and into saprolite before leveling out for the horizontally oriented screen section. However, where the bore passed through the construction debris the material was unstable and prevented the installation the HDPE well materials in the traditional manner. Therefore DTD used its proprietary, patent pending technology, to stabilize the bore and install the wells. Three of the wells required this approach, while one bore was stable enough to allow the well material installation.

The sparge wells are designed to distribute air across the width of a plume to remediate groundwater contaminated with jet fuel and its components. As with all DTD wells, the bores were completed with biodegradable drilling fluid in effort to minimize damage to the geologic formation’s hydraulic conductivity. This allows the wells to communicate as efficiently as possible with the surrounding matrix, and in turn, provide a better functioning remediation system. For additional information, email dan AT horizontaldrill.com or, info AT horizontaldrill.com