Meshoppen Creek Crossing – 1415′ of 10″

With DTD’s reputation in successful completion of difficult pipeline crossings, we were once again asked to return to Northern Pennsylvania to complete a 1415’ long crossing under Meshoppen Creek, a mid-sized trout stream. As always, avoiding Inadvertent Returns was a priority, but with the job scheduled to begin days before the opening day of fishing on the trout stream, any drilling issues that might develop on the bore would become very high profile.

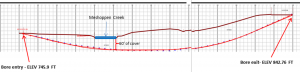

The project was complicated by a difficult geologic setting. There was an observed zone of artesian water at depth, and the relatively thick overburden (up to 50 feet) consisted of gravel and cobbles. Finally, there was a bedrock pinnacle that protruded up into the cobble and gravel horizon. Careful bore design was a priority for the successful completion of this crossing.

DTD’s American Augers DD-210 was coupled with an 800 gpm mud recycling system for the project. The rig was set up several hundred feet east of Meshoppen Creek in a small campground. Precision drilling was necessary to hit the designed bore path, drilling west, passing 60’ beneath the creek (and most of the abundant cobble, but above the known artesian water zone) then rising steeply over the next 1,000 feet to the exit, 180’ in elevation above the low point of the bore.

Once rock was encountered, drilling was slow and steady, as the unconfined compressive strength of the rock topped 25,000 psi. Finally, several site constraints required the bore to exit at a 23 degree angle, meaning the pipe handling became a significant task. Seven pieces of equipment suspended the pipe, with additional pipe rollers supporting the pipe beyond the powered equipment.

DTD coordinated with the pipeline contractor to make sure pullback of the 10-inch pipe went as smooth as possible, despite the rather steep exit angle. Communication from the exit and entry sides were crucial and the pipe was pulled into place as designed. This coordination and teaming effort proved invaluable not only during the pullback, but throughout the many difficulties of the project.