Horizontal ERH – The Fusion of Two Technologies

DTD small 10×15 drill rig installing ERH electrode

Horizontal Electrical Resistance Heating (ERH) is the integration of two remediation technologies: horizontal wells and ERH. Horizontal wells are noted for the large amount of contact they have with the contamination and access to hard to reach zones. While ERH is know for its thorough and quick remediation of contaminants.

ERH uses a grid of electrical conductors installed through the contaminated soils. Electrical current between the conductors creates electrical resistance. The resistance heats the soil, vaporizes contamination and allows removal via a co-located extraction system. In many cases, ERH systems need only a few months to clean a site.

System Installation

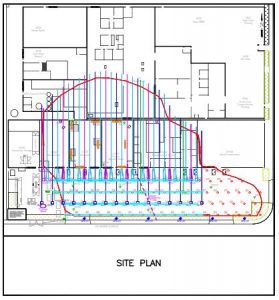

DTD is installing almost 50 horizontal ERH electrodes under a parking lot and building in a coastal California town. Each conductor contains a length of steel pipe. There are deep and shallow electrodes, and they are insulated near the ground surface to protect shallow infrastructure and limit the treatment to deeper soils. In addition to shallow and deep electrodes, soil vapor extraction wells and temperature probes wells will be installed.

Electrode layout for commercial cleanup site

The steel electrodes must have good electrical contact with the borehole walls for the technology to work. In recent months DTD developed a method to tremie the conductive fill downhole, and around the electrodes pipes. The technique allows packing of the electrodes with hundreds of pounds of the specialty carbon-based fill; a difficult task in a horizontal borehole. The fill conducts electricity efficiently from the electrode (steel pipe) to the surrounding soils.

Operations

Aerial View – DTD site for ERH electrode installation, Northern California

After DTD installs the horizontal electrodes, other contractors will install vertical electrodes outside the building footprint, make connections, and energize the system. The remediation is expected to be complete within a few months.

This is the second ground heating system installed by DTD in 2020. The previous system employees thermal conduction- essentially placing a heating element in the ground. For that project we installed sealed pipes with stainless steel liners, to encase electrical heater cans. The heaters warm to a high temperature, which then radiates heat into the surrounding soil and volatilizes contaminants.

Creative project engineers have long sought to use ERH in otherwise inaccessible areas via horizontal wells. This project demonstrates that we now have the ability to effectively bring the use of horizontal wells and ERH together to create a novel remediation system that highlights the advantages of both technologies.