Challenging 6-inch Steel Pipeline Crossing Completed

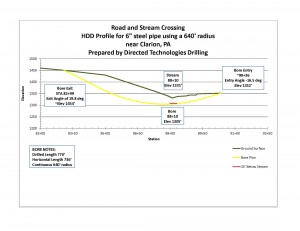

DTD has completed the second of two installations, pulling back 6-inch diameter gas pipeline near Clarion, PA. The bore crossed beneath a state highway, a small creek, and then turned upward, exiting the ground more than 100 feet above the entry location… all this in a bore less than 800′ long. A previous contractor had failed on this bore by inadvertently discharging drilling mud to the ground surface. DTD redesigned the bore to trend deeper providing more cover, and allowing the bore to be completed without any loss of drilling mud to the ground surface.

Due to the location of the bore entry at a sharp turn in the pipeline right of way, there was no space to move the drill rig further away to gain the necessary depth of cover beneath the road and the stream. To solve this, DTD planned the bore with the entry area excavated four feet below the existing ground surface. A sloped pit was excavated to match the entry angle and the drill rig was moved into place, allowing the drill bit and tooling to enter the ground lower than originally designed. By adjusting the entry elevation and then following a near continuous bend, we were able to gain a safe amount of cover beneath the road and creek to minimize any potential for inadvertent drilling mud returns back to the surface and also minimizing risk of road subsidence at a later date. The bore was completed to a final length of 770 feet.

View of drill rig at entry, looking up the bore path.

Our Vermeer 36x50DR was used to complete this bore. The small footprint of this rig, teamed with a low mud flow mechanical motor, proved to be an ideal drilling assembly for this situation. The dual rod technology is designed for drilling in rock and hard formations while minimizing the mud flow needed for cleaning and still being able to navigate the pilot bore.

DTD has found that many pipeline crossings are loosely designed with what ends up being an unsafe geometry. The bore profiles may be drillable, but often include too sharp of a turn for either the drill rod or the gas pipeline to negotiate, or, as was the case for this bore near Clarion- the profile did not provide adequate depth below infrastructure/natural resources. DTD carefully reviews the topography, geology, and bore profile before undertaking any HDD crossing to ensure we minimize risk to the pipeline, and any overlying infrastructure, all-the-while protecting the sensitive natural resources above.