Blind Injection Wells Installed Using Knock Off Tech

Often scenarios arise where clients call upon directional drilling to place well screen in areas otherwise inaccessible to vertical drillers. On top of that they often request that the wells extend long distances and terminate under ground (“blind” wells) due to restricted access. i.e., because the well is long, there is no way to accommodate operations at the distal end of a double-ended well.

With these scenarios becoming more popular, DTD has continued to perfect our proprietary Knock-Off drill bit technology, which enables us to install horizontal wells through the drill string. This technology was put to use recently at a site in California to augment ongoing remediation efforts with vertical wells to inject natural soybean oil and sugars in a tetrachloroethylene plume. The oil and sugar provide a food source for bacteria, which destroy TCE concentrations in groundwater.

CMS 9030 drill rig setup along bank of wetland. Distal end of horizontal wells is near distant treeline.

Part of the plume at this decommissioned manufacturing facility extends under a protected marsh/wetland that could not be accessed with vertical rigs. DTD set up a CMS 9030 horizontal drill rig in the upland area adjacent to the marsh and drilled two 610′ long wells beneath the wetlands. Both wells followed the same surface bore path, with a vertical separation of 10′ between the wells (one shallow at 19′ bgs, and one deep at 29′ bgs). The wells were designed to stay within two separate loose sand aquifers that were separated by a clay aquitard.

Using the Knock-Off drill bit technology, DTD precisely located the borepath and drilled to the designed well screen position beneath the marsh. Once the drilling was completed, DTD installed the well materials through the middle of the drill rods to knock off the sacrificial drill bit, then removed the drill string, leaving the well materials in the exact position where the drill rods were advanced and located. Both wells were installed in seven days and the Knock-Off technology proved to be a valuable method to prevent collapsing sand from caving into the bore, which would have hindered well screen installation if conventional open-hole technology had been used.

Distal end of bore path (pink flags) between two vertical wells where 1/2 foot of draw down was observed during pump test

Once the wells were installed and developed, DTD returned to the site to conduct a pump test and video inspection of both wells. Each well was pumped at 40 gpm for ~1.75 hours (~4,000 total gallons/well). About a half a foot of draw down was seen within two vertical wells ~30′ laterally from the distal end of the horizontal wells, demonstrating the wells have radii of influence of at least 30-40 feet (even at the distal end!). With well screens of 440 foot length, this equates to a treated zone of a minimum of 60 x 440 feet (26,400 square feet) or over a half-acre of coverage. In contrast, vertical wells at the site had a reduced radius of influence; required a well seal, cover and concrete pad for each of the dozens of wells installed; required a separate injection at each well site; and could not access the marshland directly.

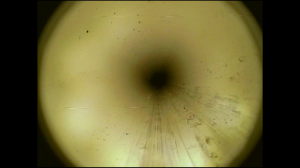

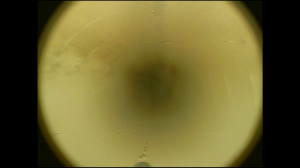

After pumping, a borehole camera was pushed down the length of each well, which provided a final visual inspection of the well integrity.

Picture captured during well video inspection within screen section (see slots to the upper left) ~460′ in